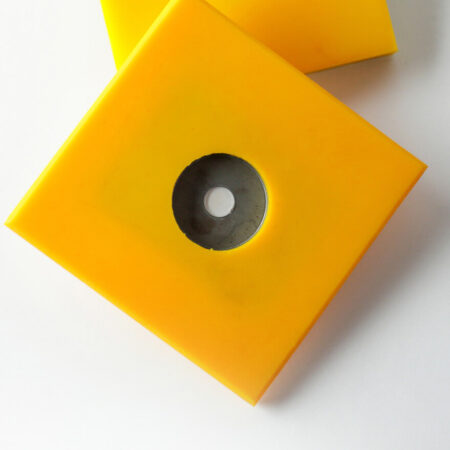

Uramic Panels

Where neither ceramic nor polyurethane alone can do the job, Uramic Panels are the ultimate solution for applications where severe abrasion is an issue. That’s because Uramic Panels combine the superior cut and abrasion resistance of ceramic tile with the impact resistance and resiliency of Rhino Hyde. For decades in the aggregate, coal, fly ash, glass, grain, gravel, cement and other industries, our panels have successfully replaced plain or weldable ceramic tile in areas experiencing frequent tile breakage.

NOTE: Recommended for Chutes, Belt Overshot Areas, Hoppers, Impact Areas, Deflector Plates, Transfer Areas

NEED A QUOTE ON WEAR PARTS?

WHAT MAKES URAMIC TOUGH TO BEAT:

- No fabrication, cutting or machining needed to install

- Reduces downtime, labor costs and waste

- Complies with the FDA standards for handling dry bulk foods

- Panels are manufactured in a modular design

- Available temperatures:

Standard (190˚F, 88˚C)

High (220˚F, 104˚C)